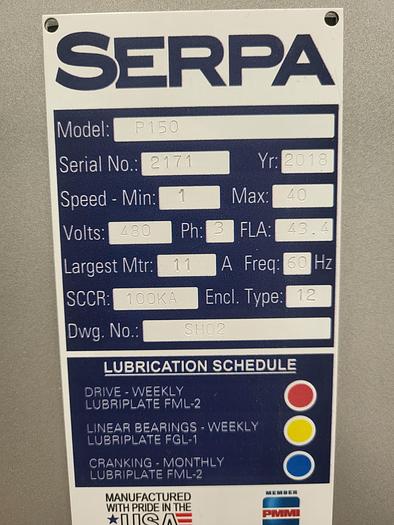

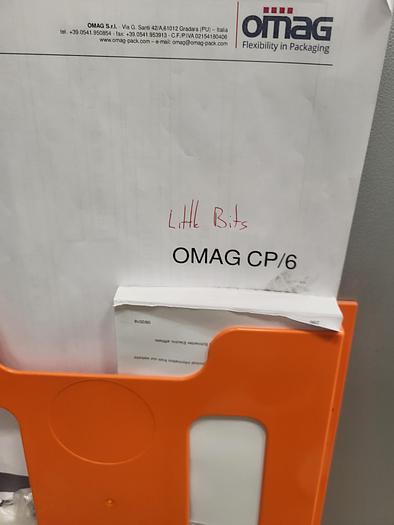

OMAG CP/6 PHARMACEUTICAL Vertical packaging machine and SERPA P150 cartoner line (2018)

OMAG CP/6 PHARMACEUTICAL Vertical packaging machine and SERPA P150 cartoner line (2018)

$299,999 (USD)

Available quantity:1

Description

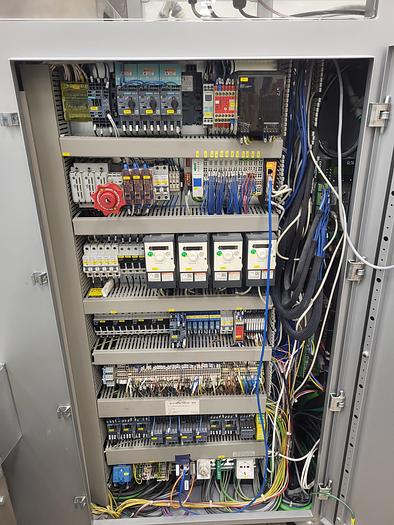

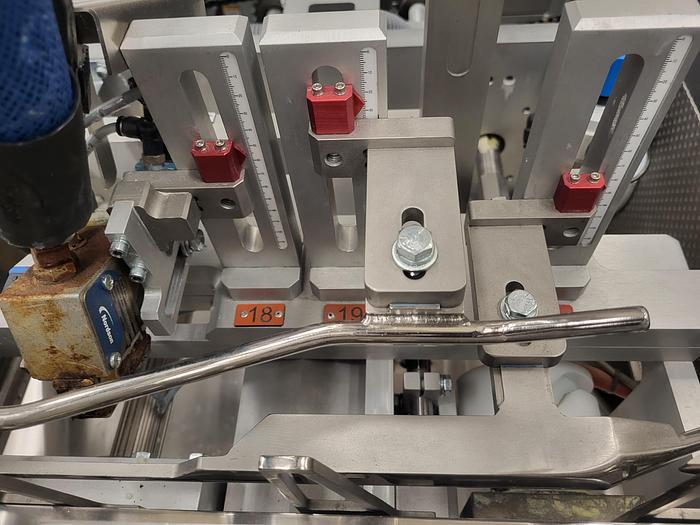

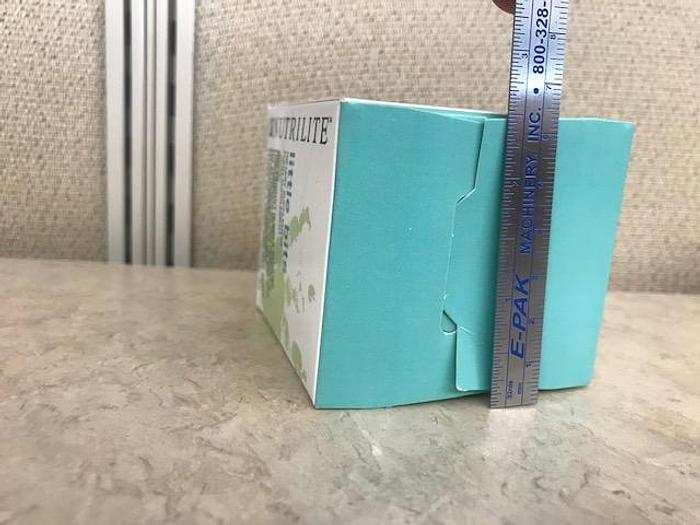

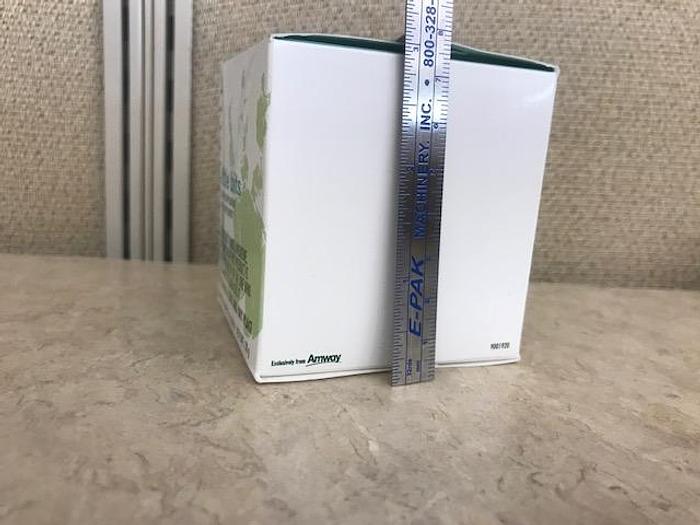

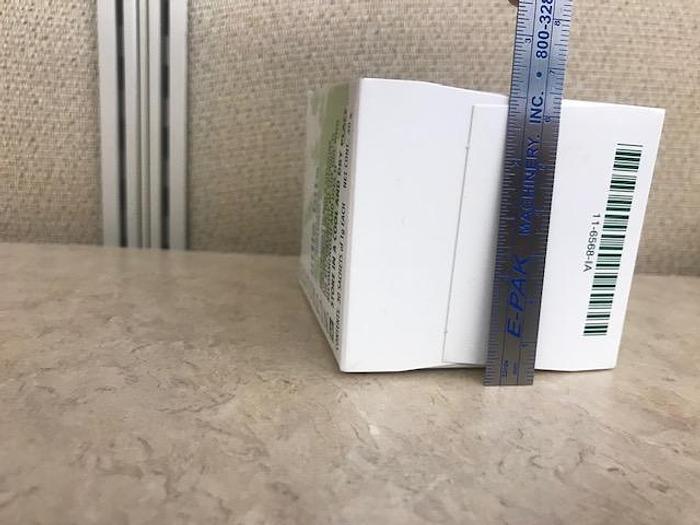

Omag CP/6 VERTICAL PACKAGING MACHINE WITH SEALING PLATES FOR SHAPED AND 4 SIDE SEALED SACHETS. set up for 1 Gram pouches, integrated with a Serpa P150 cartoner. Machine was new in 2018 and was just removed from service. See pictures for current product setup. Feel free to reach out to us for more information.

fully suited for filling 1-3gr of powdery product at speeds up to 270-330 sachets per minute (45-55 cycles

per minute), Subject to testing of bulk samples and packaging materials.

QUANTITY DESCRIPTION PRICE US$

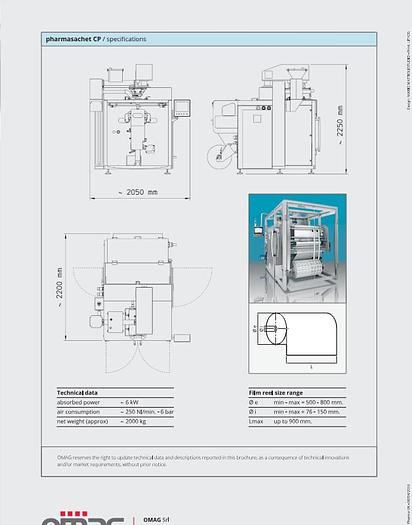

1 OMAG Sachet Machine Model CP/6, including:

CONTINUOUS MOTION VERTICAL PACKAGING MACHINE for the production of

4 side seal thermo (heat) sealed sachets.

The machines used thermo sealing film, one reel, and forms sachets in four fully

adjustable lanes according to the following ranges:

Sachet Width: 50 mm-130 mm (fixed)

Sachet Length: 50 mm – 220mm

Film Reel Width: 600mm (6 lanes of 3,600mm maximum each).

Each OMAG CP/6 includes the following excellent features:

Solid welded frame manufactured from in welded steel, painted with epoxy resin

paint, colour code: RAL 9006 (OMAG standard).

All areas exposed to the product are clad stainless steel, or are anodized aluminum

or approved plastics.

Motorized film unwinding system and electronic control of film tension, maximum

width of heat sealable material is 400mm.

Fixed support reel holder, complete with expansion shaft for reels with mm 76.2

core.

Print centering device

Vertical sealing group.

Horizontal sealing group.

Horizontal cutting group.

Automatic system for sealing rollers detachment to preserve the film from sealing

temperature during production stops.

Temperature electronic controls applied to both vertical and horizontal sealing

elements, complete with signal alarm and machine automatic stop in case of

out-of-range values.

System, placed below cutting group, to manage empty/filled sachets flow.

Electronic machine with brushless motorization.

Alphanumeric keyboard TOUCH SCREEN with alarms display and auto diagnosys.

This system allows to set/update the machine synchronism and to store several

work programs.

Accident-protection guards according to CE norms.

Required electric power: three-phase 220/380 V, 50-60 Hz + N.

Required compressed air: 6 Atm.

1 Electric US Requirements, Electric system compliance to US requirements

1 Product Level Sensor for the reservoir which can send a signal to any automatic

product transfer system (not included), and provides a product low level machine

stop safety stop.

All parts ordered before 3:30 pm (EST) typically ship same day via UPS, FedEx, or USPS! If the order is placed after 3:30 pm and you still would like it send out same day, feel free to reach out to us and we will do our best to expedite your order!

ND INDUSTRIAL SURPLUS

buyer/seller of industrial equipment, parts and machines.

We can also ship on your UPS or FedEx account.

All parts are guaranteed for 30 days!

Freight items ship 2-4 days from order date. All flat shipping rates apply to commercial shipping address with a loading dock or forklift.

Specifications

| Manufacturer | serpa |

| Model | P150 |

| Year | 2018 |

| Condition | Used |

| Stock Number | 265316263988 |